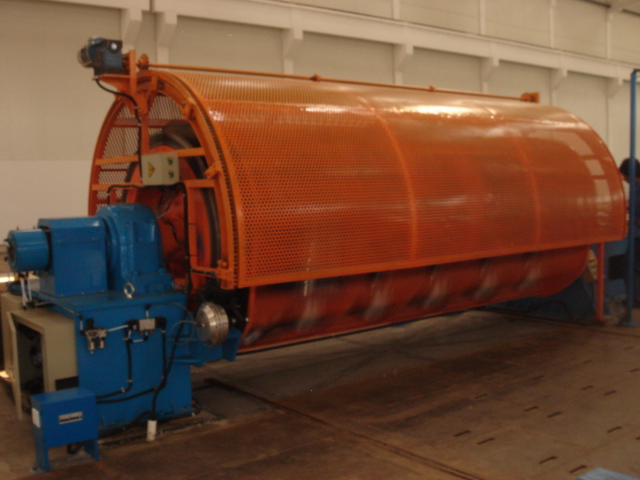

This rigid frame strander (RFS) has combined

domestic first-class stranding process and adsorbs the advantages of domestic

and international similar machines. It is convenient and efficient to load and

unload. Frame structure helps enhance the rigidity of this rigid frame

stranding machine and ensure its high rotational speed.

Compared with traditional gear box

transmission strander, rigid frame strander is characterized by lower noise

(70dB(A)), higher speed (30m/min), no leakage and maintenance free.

Features

1. Strong

rigidity

The cage and its flange are fabricated by 25mm

and 45mm steel sheets respectively, enjoying steady structure. They are tempered

and sandblasted to eliminate stress, and machined by CNC completely for high

strength. Structure design and machining of the cage makes it suitable for

working at high rotational speed.

2. High

rotational speed of cage

Diameter of stranded single wire

| AL: Φ1.5-Φ5.0mm

|

Cage speed (full/empty bobbin)

| Cage12

190/205

|

| Cage18

170/205

|

| Cage24

150/205

|

| Cage30

120/205

|

Twisted lay length

| 45-1100mm

stepless adjustment

|

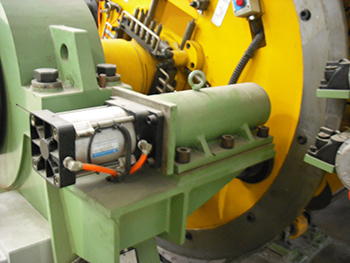

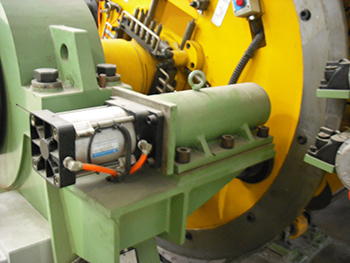

3. Built-in position sensing system is

designed to ensure the precision of loading bobbin.

The built-in position sensing system

consists of position sensor and pneumatic unit. When loading/unloading, the

signal of sensor will be transmitted to PLC, which will send command to the pneumatic

position system and lock the cage. Pneumatic brake unit is from a joint venture

in China.

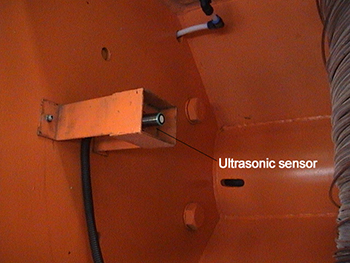

4. This rigid frame strander is equipped

with constant tension control system and intelligent brake system.

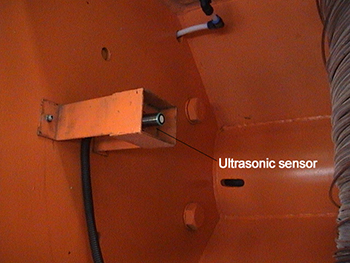

By tracking (ultrasonic) the length of wire

wrapped on bobbin, the length of wire remaining on bobbin will be detected and

transmitted to PLC. The PLC will control the air intake by proportional valve

and make the tension of wire constant. Two groups control the tension of brake

disc for paying-off to ensure the pressure on disc equal. Pneumatic brake

system is controlled by intelligent brake system. When emergently stop the machine,

the speed signal of each cage will be transmitted to PLC by sensor. PLC will

make calculation automatically and provide different brake forces to each cage

by proportional valve accordingly. The cages then will synchronously stop.

5. Converter control ensures loading

successfully in one time.

The trolley is controlled by converter, the operation is slow-fast-slow. It means the trolley starts slowly, moves quickly and approaches cage slowly. It ensures stable, reliable and precise running of trolley.

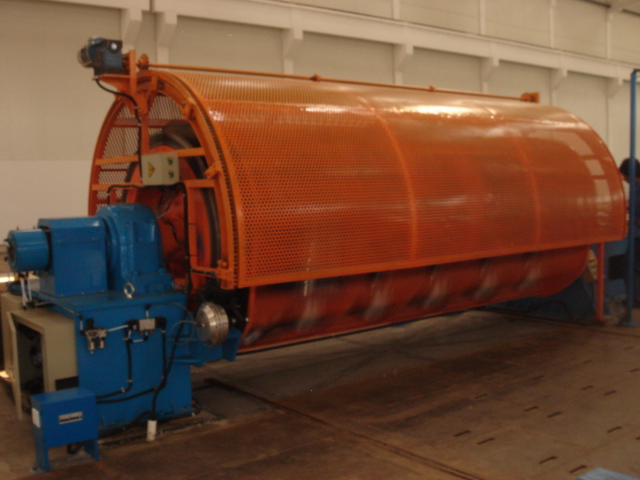

6. This rigid frame stranding machine is equipped with motorized cover.

Fully-covered unit helps to ensure safe operation. The cover will open once loading/unloading or stop of production line.

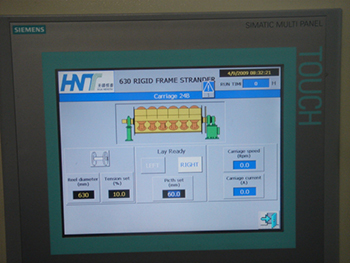

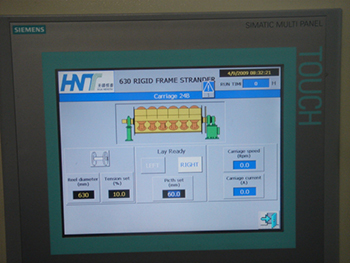

Electric control system

The synchronous control system for separate

motorized strander is different from similar strander systems by other manufacturers.

It is easy to operate by setting-up all parameters on the touch screen. Unique

program and data collection system ensure machine running stably and reliably.

The precision of lay length is less than 3% when emergency stop and less than

1% when normal stop of production line (PROFIBUS communication control).

Application

Our rigid frame strander is specially

designed to make copper and aluminum conductors as well as ACSR at high speed

and excellent conductor surface for the high-voltage cables produced in

continuous vulcanization.

Technical Data

No. of drums in cage

| 6,12, 18, 24, 30

|

Dia. of single wire

| Copper 1.5-4.5mm

|

Aluminum 1.8-5.0mm

|

Aluminum alloy 1.5-4.5mm

|

Cage rotational speed

| 6 bobbin 200rpm

12 bobbin 180rpm

|

18 bobbin 160rpm

24 bobbin 140rpm

|

30 bobbin 120rpm

|

Lay length

| 6 bobbin 37-500mm

12 bobbin 44-590mm

|

18 bobbin 52-694mm

|

24 bobbin 61-819mm

|

30 bobbin 72-1100mm

|

Line speed

| 6.9~53m/min

|

Sizes of bobbin in cage

| PND 630

|

Centre height

| 1100mm

|

Capstan

| φ2000 (2500) dual pull out capstan

|

お問い合わせ