|

|

|

This cable sheath extrusion line is used

for cable sheath extrusion or insulation.

| Screw Diameter

| L/D

| Motor Power

| Extrude Capacity (PVC)

| Extrude Capacity (PE)

|

| 30

| 25:1

| 5.5kW

| 25kg

| 15kg

|

| 45

| 25:1

| 15kW

| 80kg

| 45kg

|

| 65

| 26:1

| 30kW

| 160kg

| 90kg

|

| 80

| 26:1

| 75kW

| 260kg

| 165kg

|

| 90

| 26:1

| 90kW

| 360kg

| 210kg

|

| 120

| 26:1

| 132kW

| 620kg

| 380kg

|

| 150

| 25:1

| 200kW

| 900kg

| 550kg

|

| 200

| 25:1

| 280kW

| 1300kg

| 750kg

|

| TU32 traversing type pay-off stand

| 1 set

|

| TQD 2500kg belt caterpillar

| 1 set

|

| Φ150 × 25 extruder

| 1 set

|

| Φ140mm cross head

| 1 set

|

| Material loading and dry system

| 1 set

|

| Cooling trough

| 1 set

|

| Compression air dryer

| 1 set

|

| Electric control system

| 1 set

|

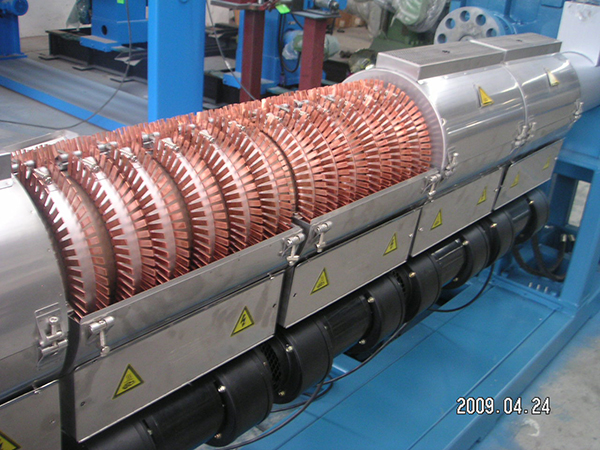

1. High

plastic extrusion capacity

The design of screw can strengthen cutting

and avoid decomposing by overheat. Fast melting of plastic can be realized in

order to extrude plastic at high speed.

2. High performance cooling system

The inner water-cooling and fan-cooling of

high-precision copper wing-piece to guarantee heating balance and precise temperature

control.

3. Special output flow path designed for

melted plastic guarantees high quality of extrusion.

4. Power-saving. This cable sheath

extrusion line consumes power of 0.18º/kg, saving more than 78% of power

compared with common extruder (0.32º/kg).

5. High performance electric control system

and temperature control instrument. Precision is ±2º. Outside diameter tolerance

of jacket is ±0.2 mm.

1. Traversing

type pay-off stand

| Reel diameter range (mm)

| Φ1600 ~ Φ3150

|

| Reel width (mm)

| 900 ~ 2500

|

| Reel weight (kg)

| 18000

|

| Suitable wire diameter (mm)

| Φ10 ~ Φ140

|

| Suitable wire moment (nm)

| 400 ~ 5000

|

| Reel up/down speed

| 0.6m/min

|

| Max. traction

| 2500kg

|

| Line speed

| 3-80m/min

|

| Suitable wire diameter

| 3-160mm

|

| Center height

| 1000mm

|

| Contact length of belt

| 2300mm

|

| Quantity of cylinder

| 8 pairs

|

| Motor type and power

| DC motor 11kW

|

| DC controller

| Eurotherm

|

| Screw type

| BM screw

|

| Screw diameter

| Ф150

|

| Scale of the length and diameter

| 25: 1

|

| Main motor power

| DC motor 180kW

|

| Roller heated power and voltage

| 120kW, 380V

|

| Quantity of roller heated area

| 6

|

| Quantity of crossing head flange

| 3

|

| Windy motor quantity

| 6

|

| Output capacity

| 650kg/h (PVC)

|

|

| 360kg/h (PE)

|

| DC controller

| Eurotherm DC controller

|

| Tough screen

| Siemens

|

| Temperature control meter

| Japan RKC

|

| PLC

| Siemens

|

| Sensor

| Japan Omron

|

| Low voltage electric equipment

| Schneider

|